Toyota targets 2027 launch for first EV with all-solid-state battery technology

The big picture: Toyota's expertise in material science and engineering could help it evolve from a technology follower to a supplier of critical EV battery components. As BMW, Honda, Mercedes, and Stellantis advance their own programs, Toyota's technical gains and supply chain strategy position it to shape the next phase of electric vehicle innovation.

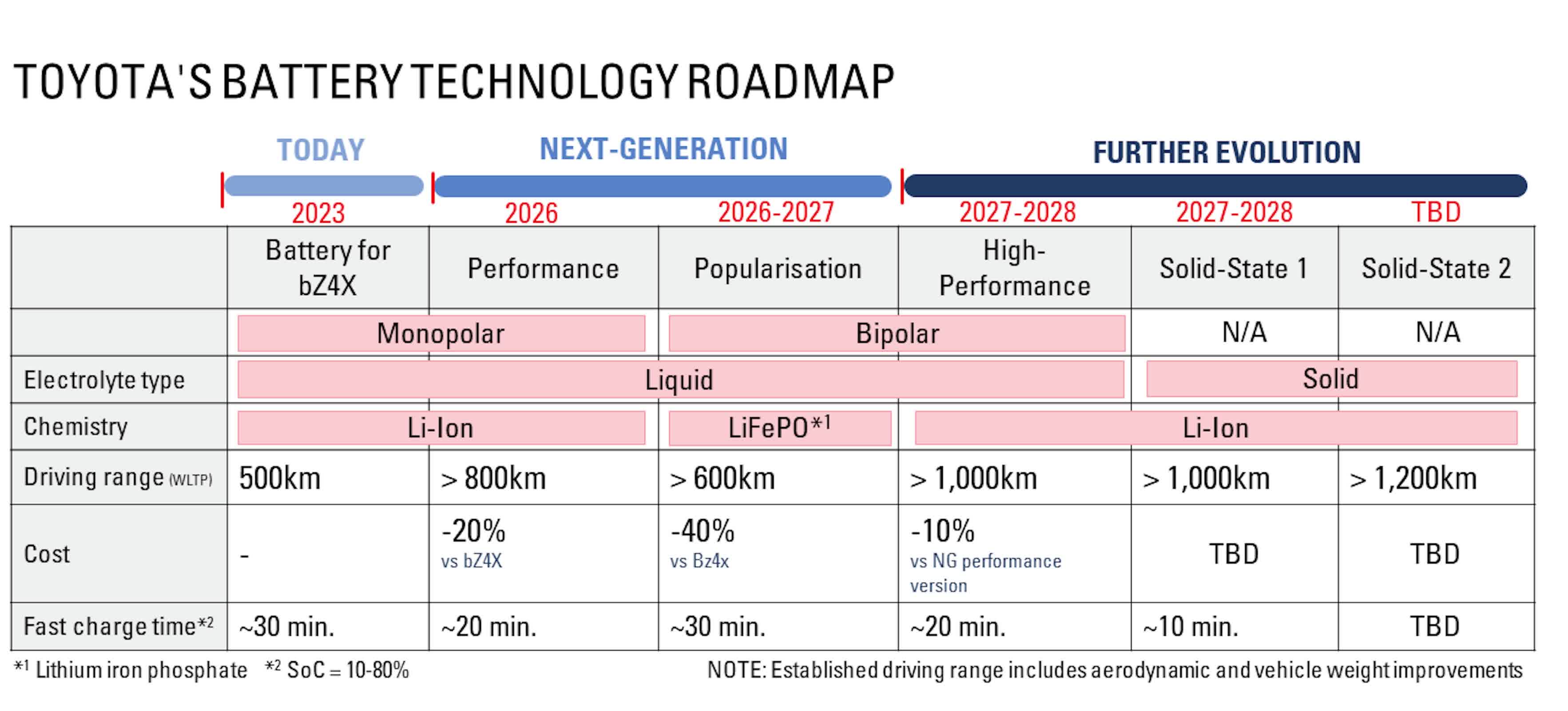

Toyota is taking a decisive step toward what many view as the pinnacle of EV technology: mass-producing all-solid-state batteries. The company plans to launch its first vehicle with this next-generation power source as early as 2027, targeting new benchmarks in range, charging speed, and performance.

Toyota's ambitions gained momentum with a new development agreement with Sumitomo Metal Mining, aimed at scaling production of cathode materials essential to all-solid-state batteries. Since 2021, the two companies have worked to refine material chemistry and durability, tackling issues such as cathode degradation that have long stalled commercial deployment. Sumitomo has applied proprietary powder synthesis techniques to create cathode materials with greater longevity and stability, engineered to endure frequent charging cycles without significant efficiency loss.

Toyota has also partnered with oil company Idemitsu Kosan, which is building a facility capable of producing 1,000 metric tons of lithium sulfide annually. A crucial solid electrolyte material for all-solid-state batteries, lithium sulfide will enter large-scale production in 2027 when the plant comes online.

These joint efforts are part of Japan's broader initiative to establish a self-sustaining supply chain for advanced battery materials and lessen dependence on China and South Korea. In total, Japanese companies have committed more than $7 billion to advancing solid-state and semi-solid-state battery research and production.

Traditional lithium-ion batteries have powered electric vehicles since General Motors introduced the EV1 in 1996. They use liquid electrolytes that are vulnerable to overheating, leading to potential safety risks like thermal runaway.

By contrast, Toyota's all-solid-state batteries use solid electrolytes, which are more stable, compact, and resistant to overheating. Combined with optimized cathode and anode materials, these batteries deliver higher energy density, greater output, and extended lifespan, while lowering fire risk and enabling faster charging. Their design also allows automakers to create light, compact battery packs, giving designers more flexibility with vehicle interiors and drivetrain layouts.

Toyota plans to keep refining its solid-state battery platform, tackling cost and manufacturability challenges before full-scale production. If progress continues at the current pace, a vehicle powered by solid-state batteries could debut in 2027 or 2028.

Global demand for advanced electric vehicles continues to grow, with many automakers exploring semi-solid-state solutions that partially replace liquid electrolytes for incremental gains. Recent launches, such as MG's second-generation MG4 with semi-solid-state batteries, demonstrate progress, but most manufacturers still rely on conventional lithium-ion packs. Toyota's focus on all-solid-state batteries could overcome critical limitations in charging speed, range, and safety, helping remove key barriers to widespread EV adoption.

As the world's largest automaker, Toyota has faced criticism for its cautious approach to electric vehicle development. If successful, its advancements could drive an industry-wide transition, establishing new standards for performance, reliability, and energy efficiency. The coming years will determine whether solid-state technology can finally deliver on its promise at scale.